Circular economy benefits as Scottish microalgae startup locks in feedstock supply from local whisky distillery

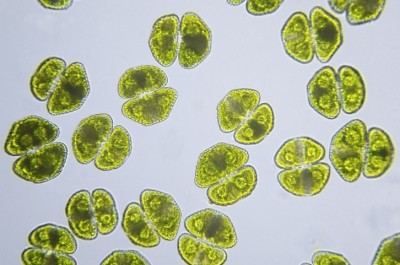

The Edinburgh-based biotechnology start-up, which has raised around £5m (US$5.9m) in investment since it was founded in 2016, has developed a biotechnology platform that uses low-value coproducts from the food and drink industry as a feedstock to initially grow microalgae rich in omega-3 oils.

Liquid co-products from Falkirk Distillery, including pot ale and spent lees, are tankered the short distance to MiAlgae’s commercial demonstrator facility in Balfron, Stirlingshire, for processing, Douglas Martin, founder and managing director of MiAlgae, told FeedNavigator.

Falkirk has an agreement with transport company Gogar in this respect and is currently supplying up to two c30kL tankers per week of feedstock to MiAlgae’s facility. “That allows us to generate up to 30 tons of algae per month," said the MD.

The malt whisky industry in Scotland alone produces about three billion liters of pot ale on an annual basis. The liquid is challenging to dispose of, and for decades the industry has been keen to develop more environmentally and economically sustainable methods to manage it.

Sustainability metrics

Falkirk said the partnership supports its goal of lowering its carbon and water footprint and making its process greener and more efficient. Founded over a decade ago, the independent distillery produces around 200,000 liters of spirit per year.

"Over the past ten years, we’ve invested everything into setting up the distillery and creating a magnificent, high quality spirit. We’re absolutely delighted to have achieved this goal and now, our next step is to become greener and to strengthen our commitment to the environment by having sustainable values embedded in our company," said Fiona Stewart, company director, Falkirk Distillery.

Using the outputs from an average distillery, of which there are 141 in Scotland alone, Martin maintains that MiAlgae's technology has the potential to save 80k tons of CO2, recycle 14.4m liters of water and protect 51,000 tons of fish annually.

“We are able to get the water cleaned to river discharge levels and estimate that every ton of algal biomass we produce will save around 40 tons of CO2 equivalent."

Product launch

In terms of outlets for its microalgae product, MiAlgae is initially targeting the pet food sector with an eye on expansion into the aquaculture sector.

“We are in the final stages of commercialization, with an initial product launch due in April 2023," said Martin.