Exosect claims breakthrough to enable efficient feeding of probiotics to livestock

Winchester headquartered, Exosect, said its researchers have shown its Entostat lean formulation technology now enables more with less in the animal feed arena, through consistent delivery of bacteria to feed pellets using Bacillus subtilis as the candidate microbial.

Jane Terry, business development manager at Exosect, told us: “The use of microbials in animal feed has been gaining significant interest in recent years due to the increase in antibiotic resistance. Entostat can be used to formulate and deliver a range of microbials including fungi, viruses and, now, bacteria.

“Seed treatment, crop protection and animal feed are all areas which could potentially benefit from this formulation technology.”

Probiotic application in feed

The company said direct fed microbials or probiotics are chosen not only on their efficacy but also by the microbial’s ability to withstand the pellet manufacturing process.

The chosen strain should tolerate the manufacturing, transportation, storage and application processes, maintaining its viability and desirable characteristics, noted Collins, Thornton and Sullivan, (1998).

The developed said an additional challenge for the external application of microbials to feed pellets and straights is the tendency for the microbial to detach from the substrate and collect at the bottom of the container.

Terry said its formulation technology gets around those challenges.

“Microbials are living organisms and as such require gentle handling. We do not expose the microbes to stresses of heat, compaction or water during formulation.

“Many effective candidates are discounted in development programs because they are not compatible with current manufacturing processes for seed treatment or feed production. Our aim is to deliver sufficient live organisms to their intended target in the most efficient way to ensure even distribution and minimize waste.”

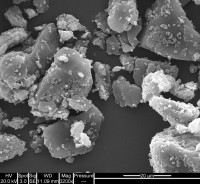

“In this instance, Entostat is formulated as a dry powder carrier for the microbials.

“When incorporated in a formulation with our patented microwax blends they become attached to the wax particles. The Entostat is then applied in minute quantities to its intended target surface where it sticks due to naturally occurring electrostatics. They are added to feed post-production or directly to grains. This can either be done at bagging or feeding,” she explained.

The technology acts as a formulation platform for a wide range of synthetic and biological active ingredients and can be formulated in dry and wet formats, she said.

The waxes used in it, continued Terry, are inert ingredients and are already used in a wide variety of industries including food manufacturing and processing.

Farm and industrial uses

The company sees opportunities in feed manufacturing and also in on-farm application.

“With the ability to deliver a range of different microbials, viruses, bacteria and fungi, Entostat is an attractive formulation tool for industrial producers of microbials and feed companies,” said Terry.

Entostat is commercially available, under license, to companies seeking to exploit this technology subject to agreed terms, she said.

The return on investment (ROI) for license holders would be dependent on a multitude of variables including the costs of active ingredients, quantities produced, intended markets within animal feed, continued Terry.

“The versatility of the platform means that a licensing partner could employ the technology across multiple products and markets.

As well as sales of their final product, our partners would have to calculate the savings achieved in R&D through not having to develop their own formulation delivery tool from scratch. Additionally, the benefit of being able to launch a microbial/microbials that would have otherwise remained unused would also have to be considered,” she added.